Custom Design

Our design team is always been an excellent platform for designers to bring their ideas to market, especially for new packaging structures. Send us your design to make free samples, and don’t worry if you don’t have a design, our experts will help you determine the packaging options that suit your needs best, and design exclusive box types. Contact us to partner on your projects.

Decoration Options

Decoration plays a vital role in the final product display. Epoch Packaging has experienced printing technicians with exquisite craftsmanship, equipped with high-end printing machines and automatic processing equipment. We provide foil stamping, spot UV, embossing, die cutting, glittering, coating, flocking, YO, and so on, as well as kinds of inserts.

Custom Packaging Manufacturing

In recent years, Epoch packaging has had long-term and in-depth cooperation with some well-known enterprises, cultural institutions, artists, and publishing to tackle technical problems in image technology, repeated experiments, developed and registered printing patents, and successfully photocopied some albums with great collection value. The average daily production capacity of the automatic folding machine is 500,000 PCS, the glue binding linkage line is 22,000 copies, and the hardcover album is 2,000 copies. The average daily production capacity of automatic die-cutting and automatic handbag machine is 72,000 PCS, and automatic folder-gluer is 120,000 PCS. Epoch packaging is also equipped with laminating, Auxiliary equipment such as coating, stamping, embossing, UV, etc. Complete packaging processing equipment provides high-quality products.

#01 Raw Material

Selecting the right raw material for custom packaging is essential to ensure the product’s protection, enhance the brand image, reduce costs, and promote sustainability.

#02 Paper Laminating

Paper laminating is a versatile process that can be used to achieve a range of benefits, from improved durability to enhanced aesthetics.

#03 Printing

Epochpackaging combine experienced engineers with our advanced printing machines to enhance production efficiency and to maximize the quality of your products.

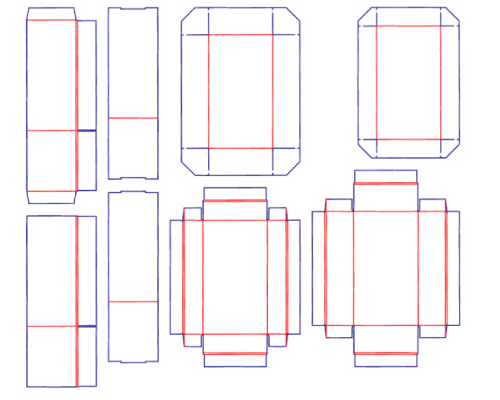

#04 Die Cutting

Cutting out specific shapes from a sheet of paper or cardboard using a specialized tool called a die. It allows for precise and efficient production of custom packaging boxes with intricate designs, patterns, or perforations.

#05 Box Gluing

Epoch packaging use environmentally friendly, non-toxic glue to make each box.To make sure your Product is safe to all your customers,and improve your brand identity.then help to expand your marketing and add your profits.

#06 Packaging

Our dedicated workers strictly enforce our packaging standards every step of the way to ensure that your package is not damaged during shipping.and make sure you can get qualified Products.

Quality Management

We fully understand that quality is the key to the survival and development of an enterprise and the basis for establishing long-term cooperation with clients. We help clients to establish brand images among consumers. Applying ISO-certified processes and stringent internal control in every aspect of production, and heavily invest digital and systematic inspection equipment to ensure that satisfy the needs and expectation of our customers.

Free Sample

We provide a free sample credit of $300 with a maximum of 20 pieces for each project, and you pay the shipping cost only. Pre-production samples can ensure that the final product and quality meet your requirements. Send us your design artwork to confirm the sample-making time.

Fast Shipping

Epoch packaging coordinates global logistic services for export to all continents. We can offer FOB, CIF, Door to Door service by sea, air, or express. Let us know your deadline, we will advise the best shipping method in the most economical way.